Revolutionizing the Production of SiO₂ Multi-Shell Hollow Spheres

Overview

- Innovative precursor hydrolysis method enables efficient mass production of SiO₂ MHSs.

- Customizable void ratios unlock vast potential for applications in various industries.

- Streamlined process dramatically reduces costs while enhancing production efficiency.

Introduction to SiO₂ Multi-Shell Hollow Spheres

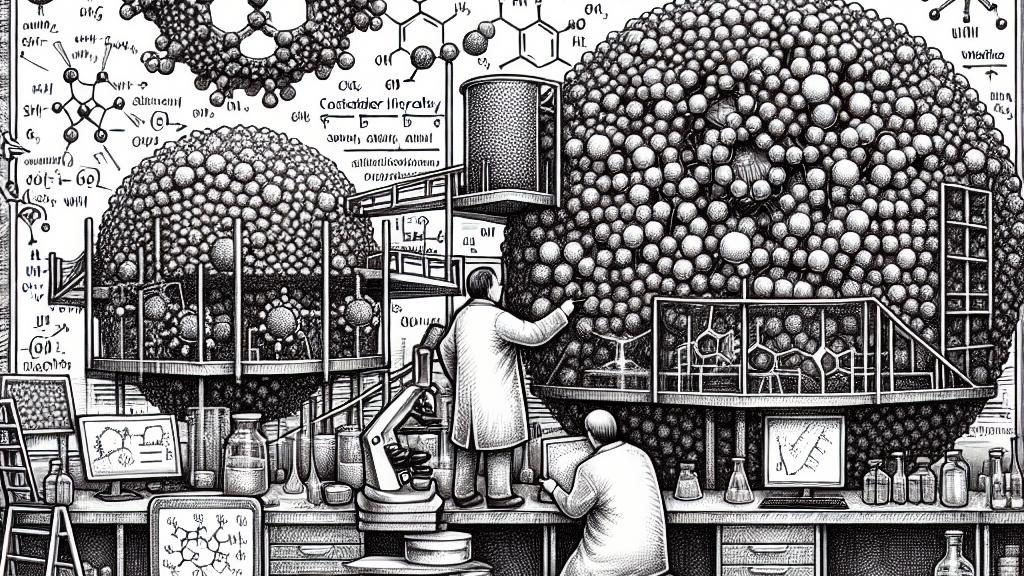

Have you ever considered the potential of silicon dioxide (SiO₂) multi-shell hollow spheres (MHSs)? Originating from groundbreaking research in China, these materials are not just a scientific curiosity; they have remarkable properties that make them ideal for diverse applications. SiO₂ MHSs feature porous walls and hollow spaces, facilitating effective mass and energy transfer as well as dynamic chemical reactions. As a result, they can significantly enhance processes in fields like confinement catalysis and drug delivery. However, the challenge has always been scaling up production from the lab to industrial levels—until now, with the introduction of an innovative precursor hydrolysis method (PHM).

The Innovative Precursor Hydrolysis Method

So, what makes this precursor hydrolysis method a game changer? Guided by the esteemed Prof. Zhu Qingshan from the Chinese Academy of Sciences, the new PHM process is designed to simplify and enhance production efficiency. Starting with the synthesis of precursors made from SiCl4 and ammonia in a fluidized bed reactor, the process has several carefully calibrated steps. The precursors undergo hydrolysis in ammonia water at a controlled temperature of 25°C for five hours, followed by a gentle heating phase. This approach eliminates the cumbersome template preparation and high temperature treatments typical of conventional processes. What’s more, by tweaking the pH levels during hydrolysis, researchers can adjust void ratios and diameters of the MHSs with precision. This flexibility empowers industries to customize material properties, making them tailored for specific applications, whether it be capturing carbon in energy solutions or delivering sensitive drugs at the right moment.

Envisioning the Future of SiO₂ MHS Applications

Looking ahead, the impact of SiO₂ MHSs on various industries is nothing short of exciting. Just imagine! With mass production capabilities in place, sectors ranging from energy to healthcare can harness these incredibly versatile structures. For instance, in the booming electric vehicle market, MHSs could be crucial in enhancing battery efficiency, enabling longer-lasting vehicles that reduce our carbon footprint. In healthcare, their customizable nature might lead to groundbreaking drug delivery systems, allowing precise medication release exactly where it’s needed, potentially transforming patient care. As the global demand for advanced materials surges, the significance of PHM cannot be overstated. It's set to propel SiO₂ MHSs into everyday applications, paving the way for a future where cutting-edge technology meets practical solutions for global challenges.

Loading...