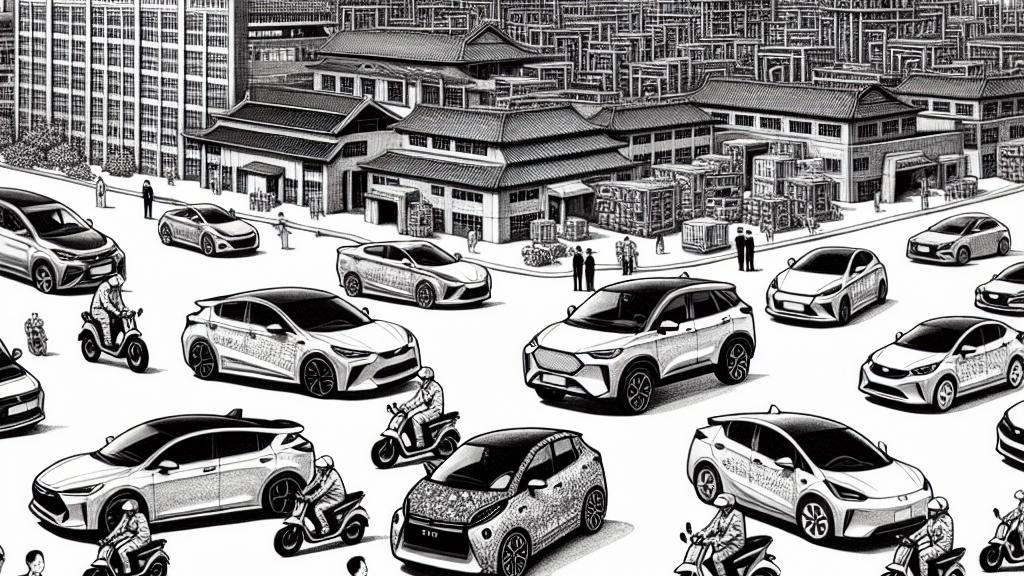

Why China Dominates the Electric Vehicle Market

Overview

- China spearheads the global electric vehicle market with its groundbreaking battery advancements.

- LFP batteries, known for their cost-effectiveness and safety, offer Chinese manufacturers a significant upper hand.

- In contrast, Japanese and Western automakers are struggling to integrate this revolutionary technology.

China's Unmatched EV Strength

In 2023, the electric vehicle (EV) market underwent a transformation, and at the helm was China, demonstrating extraordinary dominance. This isn't just a minor lead; it's a breakthrough that has left competitors from Japan, the U.S., and Europe scrambling to catch up. The cornerstone of this dominance is the use of Lithium Iron Phosphate (LFP) batteries. These batteries are not only economical to produce but also incredibly safe compared to traditional Lithium Nickel Cobalt Manganese (NCM) variants. What does this mean financially? Well, consider how a typical electric car might cost around ¥2 million to produce in China; a mere ¥500,000 of that goes towards the battery itself. Meanwhile, if you're looking at a similar vehicle from Japan, you might be spending more than ¥1 million just on the battery! This critical cost advantage allows Chinese companies to invest in better technology and more appealing designs, creating vehicles that are competitive in both performance and price. And as the global push for sustainable transport intensifies, this gap is likely to expand unless Japanese and Western carmakers can quickly adapt their strategies.

The Pivotal Role of Battery Technology

In the electric vehicle realm, battery technology is the linchpin that fuels the entire industry. It’s staggering to realize that the battery often constitutes over half of an EV's production cost—this fact alone makes it crucial. For instance, if you're manufacturing an EV in China for ¥2 million, approximately ¥500,000 is allocated for the battery. In stark contrast, the same vehicle produced in Japan or Europe might see battery costs skyrocketing to over ¥1 million, creating a massive hurdle for competitiveness. This disparity not only limits the ability to offer competitive prices but also restricts investment in essential aspects like innovation and performance enhancements. To add another layer, LFP batteries are celebrated for their longevity and safety—they don't ignite like traditional batteries do, making them a more reliable choice. Thus, for Japanese and Western manufacturers to level the playing field, they must find ways to secure affordable battery solutions or risk being sidelined by the rapidly advancing Chinese EV market. The stakes have never been higher, and the clock is ticking!

Loading...