Understanding Structural Defects in Amorphous Solid Deformation

Overview

- Structural defects are crucial to understanding how amorphous solids deform under stress, shedding light on their mechanical behavior.

- Innovative experiments using colloidal glasses unveil significant insights, linking microscopic observations to macroscopic effects.

- These findings open new avenues for material design, promising enhancements in durability and performance across various industries.

The Essential Role of Structural Defects

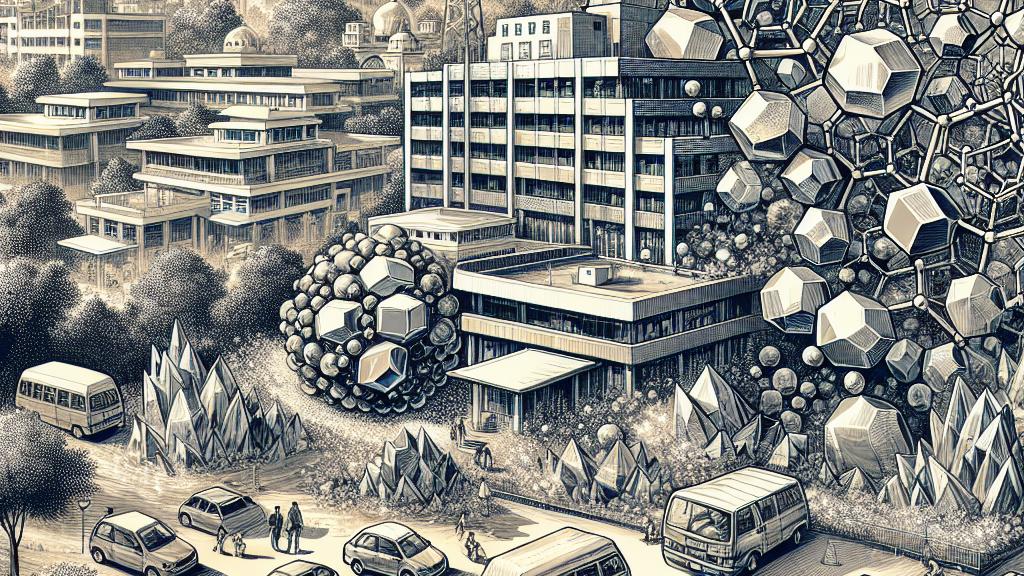

In the bustling city of Pune, India, an outstanding collaboration between researchers at the Indian Institute of Science Education and Research (IISER) and the CSIR-National Chemical Laboratory has led to an extraordinary breakthrough. They discovered that structural defects are not just flaws; they are fundamental to how amorphous solids behave when stretched or compressed. Unlike crystalline materials, where the arrangement of atoms is orderly, amorphous solids present a jumbled structure that complicates defect identification. For example, when these materials encounter external forces, it becomes evident that deformation initiates in defect-rich areas. This critical insight not only answers long-held questions in materials science but also underscores the importance of these defects in influencing the overall mechanical properties, much like how cracks can expand and propagate in a fragile glass.

State-of-the-Art Experimental Techniques Unleashed

The team’s approach to experimentation is nothing short of revolutionary. By using dense colloidal suspensions as analogs for amorphous solids, researchers meticulously followed nearly 100,000 particles over time with groundbreaking microscopy techniques. Imagine witnessing a dynamic ballet, where each particle reacts uniquely under applied stress! Remarkably, the researchers developed a structural order parameter, a tool that quantifies the soft and hard regions within these systems. This parameter is invaluable because it enables researchers to translate complex microscopic behaviors into coherent macroscopic outcomes. For instance, through their detailed analysis, they demonstrated that localized deformations in regions filled with defects often lead to significant, observable changes in the material's overall integrity. Such detailed understanding allows material scientists to visualize and manipulate the behavior of solids in real-time, bridging the gap between theory and practical application.

Transformative Implications for Material Design and Industry

These groundbreaking discoveries hold transformative potential for material science, extending their implications far beyond laboratory settings. With a nuanced understanding of structural defects and their impact, engineers can now design materials that boast superior durability and adaptability. Envision robust and flexible packaging for delicate items, advanced aerospace materials that withstand extreme conditions, or even next-generation medical devices designed for longevity and reliability. Each application exemplifies how insights gained from the study of amorphous solids can result in tangible benefits across industries. Ultimately, the research not only enhances our comprehension of how materials behave but also paves the way for innovations that could dramatically improve our quality of life, illustrating the profound connection between fundamental science and everyday technology.

Loading...