Improving Titanium Alloys with Advanced 3D Printing for Better Durability

Overview

- Titanium alloys are incredibly strong and lightweight, making them indispensable across various industries.

- Recent innovations in 3D printing are enhancing the durability and performance of these materials.

- Precise research details can lead to groundbreaking advancements in the science of materials.

The Marvel of Titanium Alloys

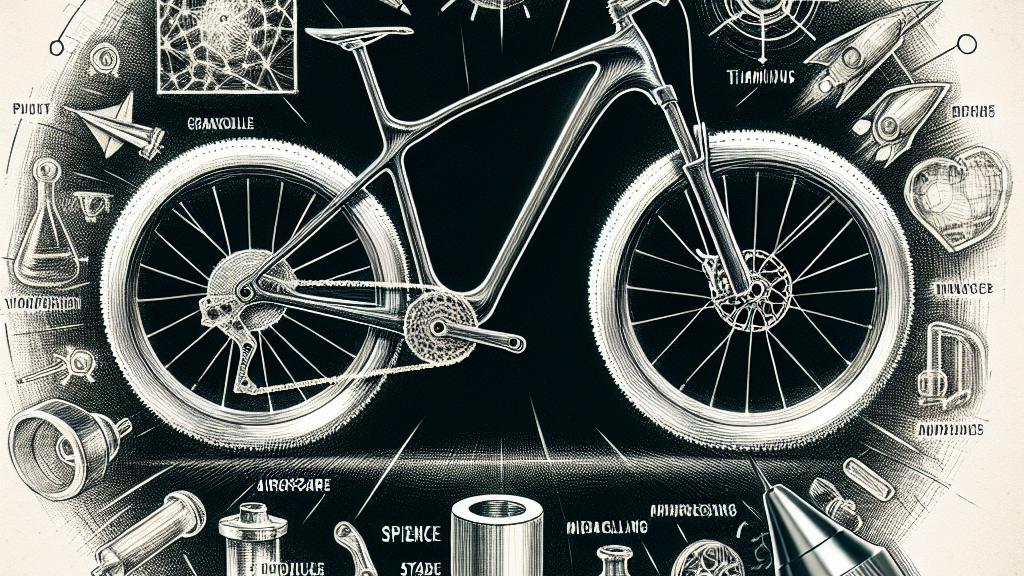

Titanium alloys are known for their exceptional strength coupled with a low weight, which makes them vital in critical applications, from aerospace to medical devices. For example, consider how planes made from titanium can soar higher and faster, with less fuel consumption due to their lightweight structure. In a fascinating study from the Shenyang National Laboratory for Materials Science in China, researchers demonstrated that using advanced 3D printing techniques, they could create titanium components that are nearly void-free. Imagine riding in a bike whose frame is crafted from such sophisticated alloy; it not only promises resilience on the roughest trails but also offers an exhilarating ride without compromising on safety!

3D Printing: A Revolutionary Technique

The emergence of 3D printing has completely transformed the way we manufacture titanium alloys, ushering in unparalleled levels of efficiency and precision. This groundbreaking method allows for the production of components with minimal void spaces, drastically increasing their strength. Picture this: traditional titanium parts may have microscopic air pockets, which can introduce vulnerabilities. In contrast, a titanium component made via cutting-edge 3D printing resembles a solid block of granite—dense, sturdy, and reliable. Such advancements mean that tools and machinery fashioned from these enhanced alloys not only perform optimally but also have extended lifespans, thus saving manufacturers time and money on replacements and maintenance while improving overall safety.

Why Precision in Research Matters

A recent correction in a scientific publication underscored just how crucial minor details are in research, particularly concerning the correct units used in graphs and data visualization. For instance, tweaking the displayed units in a figure altered the interpretation of vital data regarding titanium alloys’ properties, similar to fixing a typo in an important essay that changes the entire meaning. These precise changes enable researchers to refine their production techniques further and develop tailored titanium alloys to meet evolving demands. Each detail counts, driving forward innovation and opening doors to future breakthroughs in materials science that could revolutionize various applications, from prosthetics to aerospace engineering.

Loading...