Innovative Light-Based Microcapillary Monitoring in Biotechnology

Overview

- Revolutionary technology provides precise contact detection at the nanoscale using light.

- Key applications include enhancing techniques in IVF, advancing micro-electroplating, and refining nano-3D printing.

- This innovation is poised to transform various industries by ensuring safe and delicate interactions.

Microcapillaries: Essential Tools in Science and Engineering

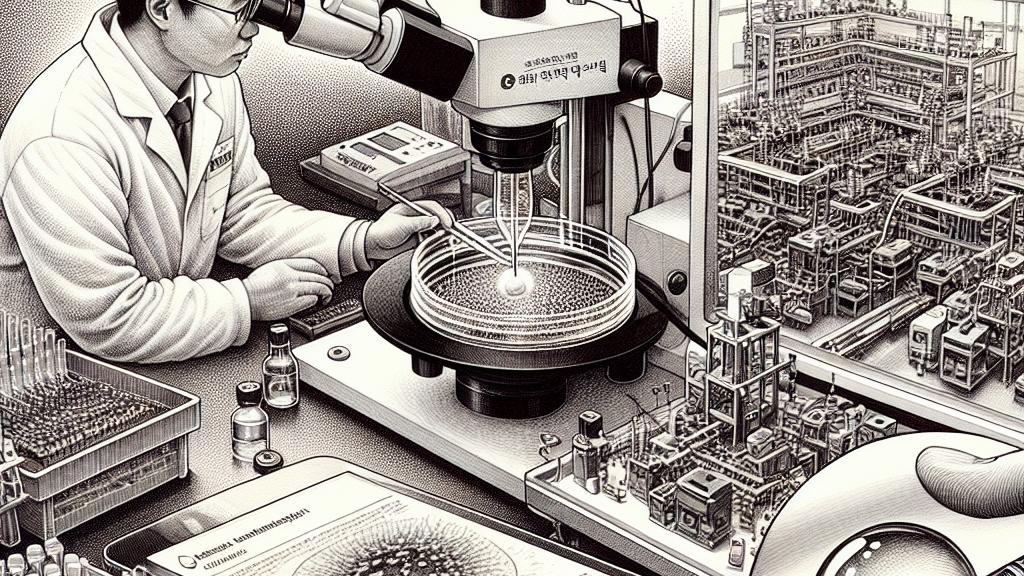

In South Korea, researchers at the Korea Electrotechnology Research Institute (KERI) are shining a light, quite literally, on the field of microcapillaries. These remarkable glass tubes, with diameters as minuscule as 0.00001 mm, serve as indispensable tools across a plethora of disciplines. For instance, in biotechnology, they are crucial for intricate processes such as injecting sperm into eggs during in vitro fertilization (IVF), which can directly impact the success rates of assisted reproductive technologies. Additionally, in the manufacturing sector, microcapillaries play a vital role in the precise creation of electronic components—from microprocessors to miniature sensors. However, the delicate nature of these tools presents a significant challenge: ensuring that the contact between the microcapillary’s tip and the target object is both safe and accurate.

Harnessing Light: A Breakthrough in Contact Detection

To tackle this daunting challenge, Dr. Jaeyeon Pyo and his innovative team have pioneered an ingenious method that relies on the principles of light. Traditionally, scientists turned to optical microscopy for contact detection, yet this approach falls short at the nanoscale level. By projecting light into the microcapillary, they created a groundbreaking system where the behavior of light at the tip becomes an accurate indicator of contact. Imagine this scene: when the sharp tip of the microcapillary is free, it scatters a bright light; however, as soon as it touches an object, that dazzling light vanishes in an instant. This elegantly simple yet profoundly effective technique transcends the limitations of previous methods, allowing for immediate and reliable feedback in various intricate applications. Notably, it enhances the precision of nano-3D printing and micro-electroplating, ensuring that even the tiniest electronic components can be produced with extraordinary accuracy.

Transforming Industries: The Far-Reaching Impacts of Innovation

The ramifications of this remarkable technology extend far and wide, heralding a new era for multiple industries. With this advanced detection method, microcapillaries can now interact with utmost delicacy and accuracy, which can substantially improve biological research. For example, in cell biology, this development paves the way for more effective penetration of cell membranes, a critical factor in studying cellular mechanisms and drug delivery methods. Moreover, in the manufacturing realm, this technology promises to revolutionize microelectronic fabrication through enhanced control in electroplating processes, ultimately leading to more reliable and efficient production solutions. As KERI moves forward with patenting this pivotal innovation, it is likely to draw considerable interest from various sectors eager to enhance their processes and outcomes. This remarkable advancement not only showcases the brilliance of scientific ingenuity but also emphasizes how the convergence of light and micro-engineering can lead to significant breakthroughs in biotechnology and manufacturing, opening new horizons for future exploration.

Loading...