AI Product Anomaly Detection System Like a Photo Studio

Overview

- Hutzper's Mekiki Baito reimagines product inspection by delivering stunning image clarity.

- Dynamic lighting and conveyor adjustments provide unprecedented accuracy in evaluations.

- Unveiled at FABEX Kansai 2024, it stands at the forefront of AI-driven quality control.

Mekiki Baito: Changing the Game in Quality Inspection

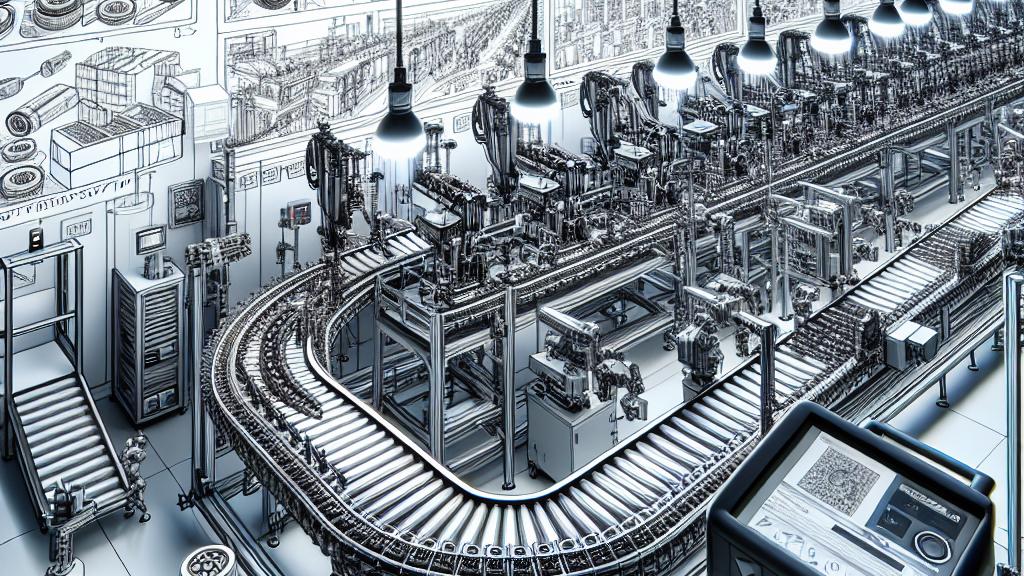

Welcome to a new era of product inspection with Mekiki Baito, an innovative creation by the Japanese company Hutzper. Imagine walking into a manufacturing facility where the inspection line feels less like a dreary, industrial space and more like an upscale photography studio. This transformation is not just aesthetic; it's deeply functional. Mekiki Baito focuses on producing exceptionally high-quality images tailored to the specifics of each product being scrutinized. With a keen attention to detail, the system meticulously adjusts lighting, conveyor belt colors, and other essential settings, all designed to optimize image capture. For example, this custom lighting setup ensures that even the faintest defects become visible, allowing the AI to analyze images with remarkable accuracy.

The Vital Role of High-Quality Images in Anomaly Detection

Why does image quality matter so much in product inspections? The answer lies in today's fast-paced manufacturing world, where every single detail counts. High-quality images are crucial, as they can make the difference between a flawless product and one that fails to meet quality standards. Conventional inspection methods often fall short, plagued by inconsistent lighting and environmental variations that can obscure vital details. Mekiki Baito effectively tackles these issues through its innovative design and technology. During an eye-opening demonstration at FABEX Kansai 2024, the system wowed onlookers by capturing images with such clarity that even the tiniest flaws on food packaging were illuminated. This capability is not merely advantageous; it directly correlates with increased product reliability and customer satisfaction.

Astounding Real-World Applications and Tangible Benefits

But Mekiki Baito is more than just a sophisticated inspection tool—it symbolizes a significant leap forward in automated quality assurance. By effectively reducing human errors, it fosters greater confidence in product quality and reliability. Imagine this: with the ability to process 20 to 30 evaluations per second, manufacturers can promptly rectify any shortcomings, thus ensuring higher efficiency in operations. Moreover, the system's real-time alert features empower manufacturers to take immediate corrective actions, should any anomalies arise. This proactive strategy is not just about fixing issues—it's about cultivating a quality-centric culture within organizations. As industries increasingly embrace smart technologies, Mekiki Baito serves as a beacon of innovation, illustrating how quality control can evolve into a process that's both fast and flawless.

Loading...