Innovations in Nanostructure Fabrication Using Laser Technology

Overview

- Revolutionary method achieves direct writing of detailed nanostructures on Au nanofilm with unprecedented precision.

- This approach effectively overcomes traditional lithography obstacles, leading to more efficient and economical fabrication.

- Exciting potential applications in nanolithography and nanowelding promise to reshape the future of nanotechnology.

Remarkable Breakthrough in Nanotechnology

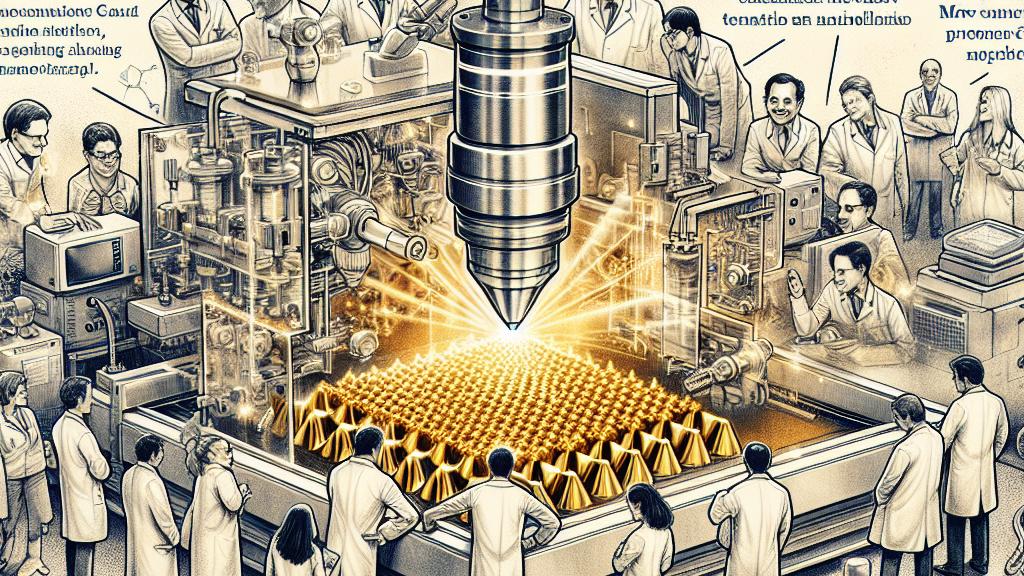

At Xi'an Jiaotong University in China, an extraordinary breakthrough in nanotechnology has emerged. Led by the brilliant minds of Xuesong Mei and Jianlei Cui, a dedicated research team has devised an innovative approach for directly writing intricate nanostructures onto gold (Au) nanofilms. This revolutionary method employs a cutting-edge laser system that dramatically pushes the boundaries of conventional optical lithography and electron beam techniques. For example, they have achieved astonishingly small subwavelength nanostructures, boasting an impressive minimum linewidth of just 83.6 nm. This achievement is not merely a technical feat; it represents a thrilling opening to new possibilities in the world of nanofabrication.

Exploring Technical Excellence

Central to this groundbreaking advancement is a sophisticated system that masterfully combines a cantilevered scanning near-field optical microscope (SNOM) probe with a high-powered nanosecond laser. This dynamic combination allows for the precise writing of complex patterns without the cumbersome reliance on masks or vacuum environments. Moreover, the process involves the melting of the gold nanofilm, with outcomes intricately controlled by factors such as single-pulse energy and laser polarization. For instance, by manipulating these parameters, researchers not only achieve different linewidths but also enhance the flexibility of the fabrication process. Furthermore, the introduction of locally excited surface plasmon polaritons (SPPs) illuminates a fascinating aspect of this technique, revealing how the interplay of light and matter can dramatically refine nanotechnology's capabilities.

Expanding Horizons: Potential Applications

The implications of this innovative fabrication approach extend far beyond the realm of nanostructures. Researchers are ignited with enthusiasm as they envision how this technique could genuinely transform the landscape of nanolithography. This advancement has the potential to facilitate the precise design of complex nanostructures across a wide range of materials—from metals to innovative polymers. Additionally, the prospect of applying this method in nanowelding signals an economical and effective avenue for creating sophisticated nanomaterials essential for cutting-edge electronics. Imagine advanced biomedical devices that integrate seamlessly into human systems or intricate environmental sensors capable of detecting minute changes in surroundings. In conclusion, this research lays a robust foundation for future breakthroughs, inviting us on an exhilarating journey into the evolving domains of nanofabrication and material science innovation.

Loading...