Eco-Friendly Way to Make Important Chemicals Using a New Copper Catalyst

Overview

- A groundbreaking copper catalyst converts CO2 into acetaldehyde with remarkable efficiency.

- This green alternative completely replaces harmful fossil fuel methods, slashing carbon emissions.

- Scalable and cost-effective, this innovation sets the stage for a sustainable industrial revolution.

A Revolutionary Breakthrough in Chemical Production

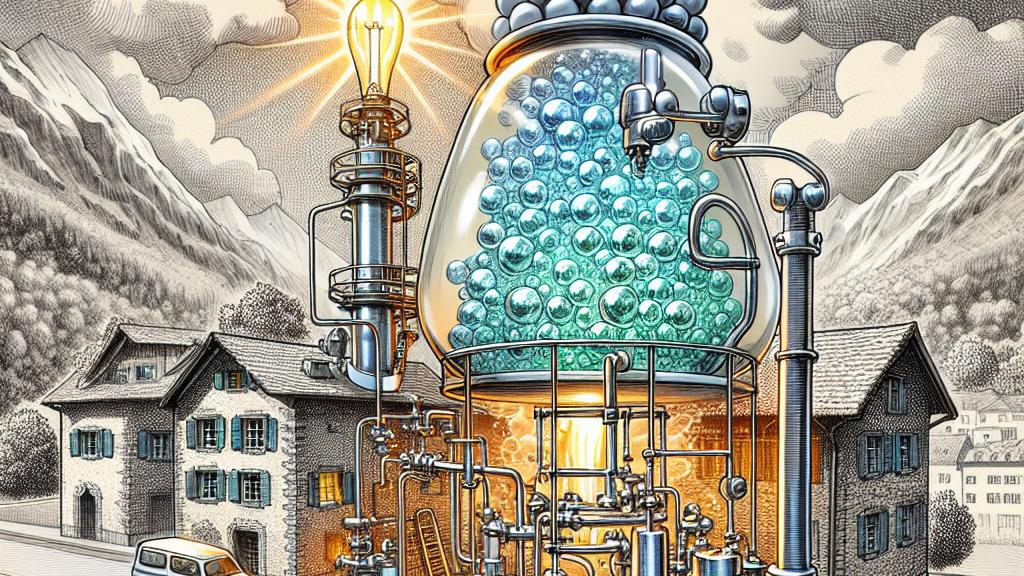

In the heart of Switzerland, researchers have made an extraordinary leap forward in sustainable chemistry. They have developed a new copper-based catalyst that transforms carbon dioxide (CO2)—largely considered a waste product—into acetaldehyde, a vital component used in countless products from perfumes to plastics. Traditionally, the production of acetaldehyde has relied on ethylene sourced from fossil fuels, which not only contributes to environmental destruction but also presents long-term sustainability issues. However, this innovative method of converting CO2 into valuable chemicals provides a two-fold solution: it not only addresses pressing environmental concerns but also produces essential compounds that society needs. Imagine the impact of turning waste gases into useful products, fundamentally changing how industries approach chemical manufacturing!

How It Works: The Science Behind the Magic

Let’s dive deeper into the fascinating science behind this catalyst! Utilizing a process called electrochemical reduction, the copper catalyst harnesses electricity to drive the transformation of CO2 into acetaldehyde. Researchers created tiny clusters of copper particles, measuring a mere 1.6 nanometers—so small that they can hardly be seen without specialized equipment. The results? An astounding 92% efficiency in converting CO2 into acetaldehyde! This remarkable statistic highlights not just a scientific achievement but also the potential for real-world application. To put it simply, imagine capturing CO2 emissions from industrial plants and using them to produce a vital chemical instead of letting them pollute the environment. This catalyst proves its mettle by remaining efficient through repeated use, showcasing stability that bodes well for future industrial applications.

Envisioning a Sustainable Future

This breakthrough in copper catalysis opens up a world of possibilities. If the chemical industry embraces this cutting-edge technology, we may soon witness a dramatic shift from antiquated practices that have dominated the field for decades. The scalability and cost-effectiveness associated with this new catalyst mean that businesses—large and small—can adopt greener methods without facing financial ruin. By producing essential chemicals while simultaneously reducing harmful greenhouse gas emissions, industries can align themselves with urgent global sustainability goals. This innovation represents not just an improvement but a monumental change in how we think about chemical manufacturing and environmental responsibility. Together, we can pave the way for a greener, healthier planet where innovation meets sustainability!

Loading...