Advancements in Polyurea Membranes for Lithium Recovery from Batteries

Overview

- Revolutionary polyurea membranes offer a sustainable solution for lithium recovery from waste batteries.

- Innovative fabrication techniques significantly enhance the performance and durability of these membranes.

- Efficient recycling of lithium batteries is essential for securing a sustainable energy future.

Innovative Recycling Efforts Evolving in China

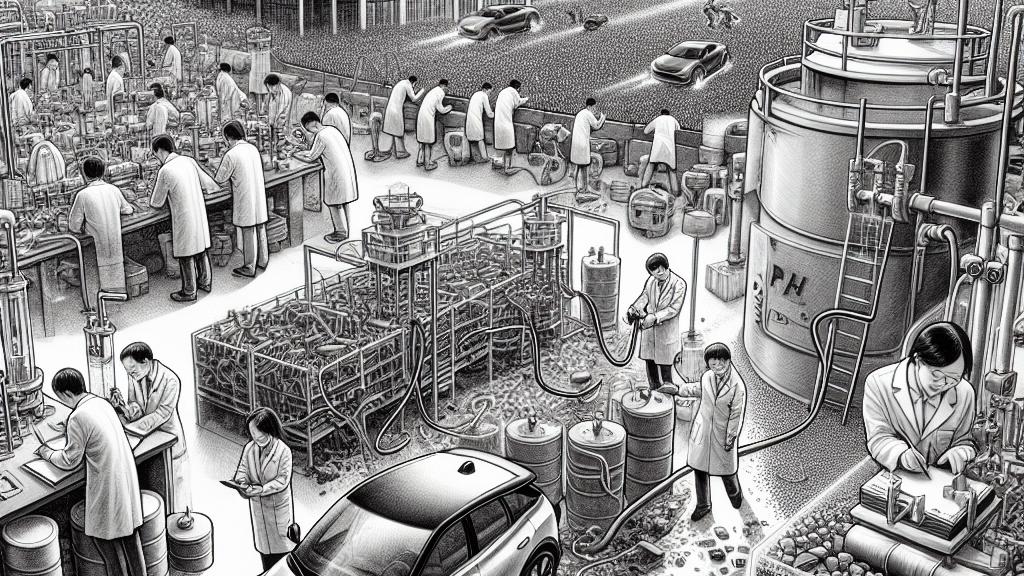

In the heart of China, a groundbreaking team from the Chinese Academy of Sciences is changing the landscape of lithium recycling with their advanced polyurea membranes. With electric vehicle sales skyrocketing and the demand for lithium resources intensifying, this research initiative couldn't be more timely. Traditional recycling methods often stumble under extreme pH conditions, leading to inefficient lithium extraction and wasted materials. However, these innovative polyurea membranes shine brightly due to their exceptional chemical stability. Testing shows that they not only withstand harsh acidic and alkaline environments but also maintain impressive lithium recovery rates. Imagine the potential: reusing precious lithium from discarded batteries, which could otherwise end up in landfills, thus contributing to a circular economy that champions sustainability.

Enhancing Membrane Technology for Optimal Performance

The key to optimizing lithium recovery lies in the meticulous engineering of these polyurea membranes. The researchers have skillfully introduced a cutting-edge zone-regulated interfacial polymerization strategy that expertly controls the diffusion behavior of monomers. This results in membranes that are not only remarkably consistent in structure but also incredibly effective in performance. For instance, the addition of Cu2+ allows for fine-tuning of reactivity, while sodium dodecyl sulfate (SDS) ensures the even distribution of materials at the phase interface. As a result, these membranes exhibit reliable separation efficiencies, setting a pioneering standard in nanofiltration technologies. This innovation highlights the critical role of chemical engineering in harnessing resource sustainability and provides a solid foundation for future industrial applications.

Global Impact and Future Directions in Lithium Recycling

The ramifications of this revolutionary research resonate far beyond China's borders; as the world shifts toward renewable energy sources, effective lithium recycling has become a global imperative. Implementing these enhanced recycling processes not only conserves precious resources but also greatly diminishes the environmental impact typically associated with traditional lithium extraction. For example, the promising direct cathode recycling method, which allows for the recovery of energy from the initial manufacturing process, illustrates a significant breakthrough. As technology advances, polyurea membranes could play an instrumental role in achieving ambitious sustainability goals, ensuring we responsibly utilize resources while meeting the ever-increasing energy demands of our society. Imagine a future where battery waste transforms into valuable resources, fostering both economic growth and environmental health.

Loading...